Overmolding, the art of seamlessly fusing multiple materials within a single mold, has revolutionized product design and manufacturing. China, a global leader in mold-making, has significantly impacted the evolution of this technology, driving advancements and becoming a dominant force in overmolding production. Let’s embark on a journey through the fascinating world of overmolding, exploring its historical roots, diving into China’s contributions, and highlighting some of the nation’s leading mold producers in this space.

A Historical Perspective: Overmolding’s Transformation

Overmolding boasts a rich history, with early signs emerging in techniques like insert molding, dating back to the early 1900s. Initially focused on simple two-shot applications, the process gradually evolved to accommodate more intricate geometries and a wider material spectrum.

Here’s a breakdown of key milestones:

Early Beginnings (1900s): Simple insert molding techniques paved the way, integrating inserts like metal components into molded plastic parts.

The Rise of Multi-Shot Molding (Mid-20th Century): Advancements in mold design and machine technology enabled multi-shot molding, allowing for the integration of more than two materials within one over mold. This opened doors for creating products with greater functionality and complex features.

Automation Revolution (Late 20th Century – Present): The integration of automation and robotics into overmolding significantly boosted production efficiency and speed. Advanced quality control techniques further ensured consistent and high-quality overmolded parts.

China’s Rise as an Overmolding Powerhouse:

China mold-making industry has played a crucial role in propelling overmolding forward, thanks to several key factors:

Cost-Effectiveness: Chinese manufacturers offer competitive pricing for overmolding projects, making this technology accessible to a broader range of manufacturers, especially for high-volume production runs.

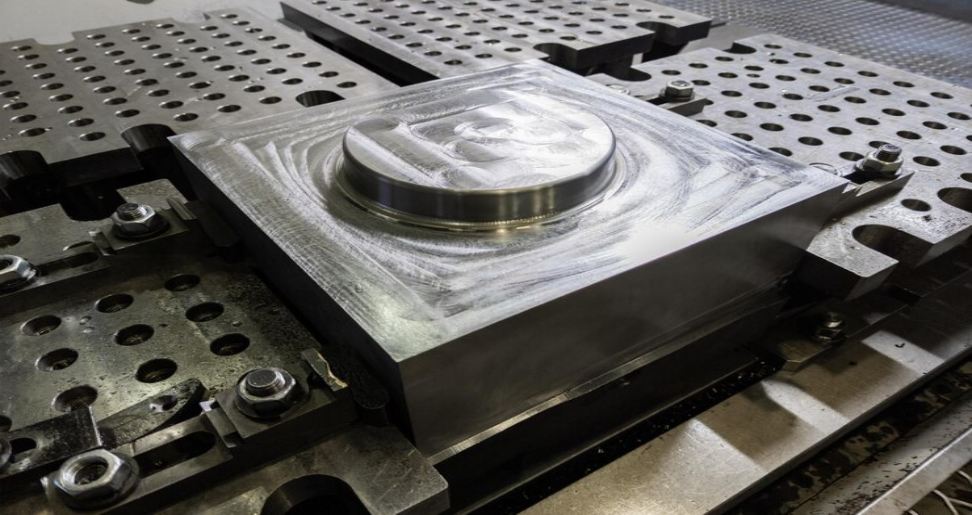

Technical Expertise: Chinese mold makers have honed their skills in overmolding techniques, including multi-shot and insert molding. This expertise allows them to tackle complex overmolding projects, catering to diverse industries.

Material Innovation: China actively explores new materials for overmolding applications, from bio-based materials to conductive plastics and high-performance thermoplastics. This expands design possibilities and caters to evolving needs.

Leading the Charge: Top Overmolding Mold Producers in China:

China boasts a vibrant landscape of overmolding mold producers, each with its unique strengths. Let’s explore some of the frontrunners:

JIGNXIN: Renowned for its expertise in custom overmolding solutions for electronics, appliances, and automotive industries. They offer two-shot and multi-shot capabilities with a strong focus on high-precision and stringent quality control.

Richfields Corporation: A leader in plastic injection molding and overmolding, offering a one-stop shop for design, mold development, and production. They cater to diverse industries and emphasize close collaboration with clients for optimal results.

Precision Machining Services (JPM): Specializes in custom plastic injection molding and overmolding, delivering high-tolerance parts with exceptional surface finishes. They excel in creating overmolded components for the medical and electronics sectors.

Topworks Plastic Mould: Offers a comprehensive range of mold-making services, including insert molding and overmolding solutions. They are recognized for their expertise in material selection and process optimization specifically for overmolding applications.

A Glimpse into the Future of Overmolding in China:

As China continues to be a driving force in overmolding, we can expect exciting advancements in the following areas:

Sustainable Practices: Chinese mold producers are increasingly focusing on eco-friendly materials and processes for overmolding, promoting sustainability within the manufacturing chain.

Integration with Automation and Robotics: Further integration of automation and robotics will enhance production efficiency, improve consistency, and potentially enable mass customization through overmolding.

Advanced Materials and Techniques: Continuous research and development efforts will lead to the exploration of new materials and advanced overmolding techniques, pushing the boundaries of design and functionality in future products.

Conclusion:

China’s mold manufacturing industry has undeniably shaped the evolution of overmolding technology. The nation’s dedication to cost-effectiveness, technical expertise, and material innovation has made overmolding a widely adopted and valuable tool for global manufacturers. As China continues to invest in automation, sustainable practices, and advanced materials, we can expect the future of overmolding to be even more groundbreaking and transformative.

Read more: